How to Heat a Warehouse: The Ultimate Guide

Heating a warehouse can be a difficult task, but it is important to install a system that ensures all employees working in the warehouse can do so in a comfortable environment and that any products stored within the warehouse are not affected by any adverse changes in temperature. There are other factors that need to be considered, such as the size of the warehouse, the climate, and the type of insulation. In this guide, we will walk you through the process of heating a warehouse and provide you with tips on how to do it effectively.

How Much Heat Do I Need?

Once you have established the size of the warehouse, you need to calculate the amount of heat that will be required to warm it up. This can be done by using a heating calculator or by contacting a heating contractor such as Winrow Building Services. The calculation will need to account for the effectiveness of the insulation within the building, as well as taking account of internal and external temperatures.

Warehouse Size?

The first step is to determine the size of the warehouse space that needs to be heated. You will need to know the length, width and maximum height of the warehouse, then determine whether you want to heat the whole building or just certain sections of it, which can be heated and controlled as specific zones.

The Area of the Floor

Your warehouse's floor space is a precious commodity. You only have so much, and you want to make the most of it. Some of the heating system choices need sufficient floor area for them to function effectively. If you're having difficulties finding room for your operations on the ground, you may have to look at alternative heating solutions. Heating your warehouse through the roof is one such solution. This can be done with gas heating, electric heating or even a solar thermal system.

The Distribution of Heat

The next thing to consider is heat distribution. Examine your warehouse to see if there are any major obstacles to heat flow. You may find that racking, for example, limits the amount of heat that can be dispersed throughout the space. When constructing your heater placement, you must therefore take this constraint into account. The goal should be for heat to be distributed equally across the whole facility.

Storage Shelving

Shelf racks are a standard piece of equipment in many warehouse settings, which allow you to easily store your products, freeing up space and reducing floor area usage. The difficulty with racking and attempting to heat your facility is that it might obstruct the flow of heat throughout the building.

It is vital to note that radiant heating only heats what it can see directly. If the infrared heat generated by the heater is unable to directly contact with the racks or objects covered by them, it cannot warm that region. Warm air heating may be a preferred option if you have a lot of racking in your warehouse. Radiant heat is ineffective at heating the air around racking because of its limited ability to penetrate solid objects.

What Heating Options Do I Have For My Warehouse?

The next step is to determine the type of heating system that will be the most efficient and cost-effective for your warehouse. When it comes to heating a warehouse, there are several alternatives. Radiant heat is a popular option for warming an entire space since it is an efficient and successful method of heating the whole area. Commercial heaters for warehouses fall into two categories: warm air heating and radiant heating. Understanding the benefits and drawbacks of each of these heating choices might help you determine which one to utilize to heat your warehouse.

So let’s look at warm air heating and Radiant Heating in a bit more detail:-

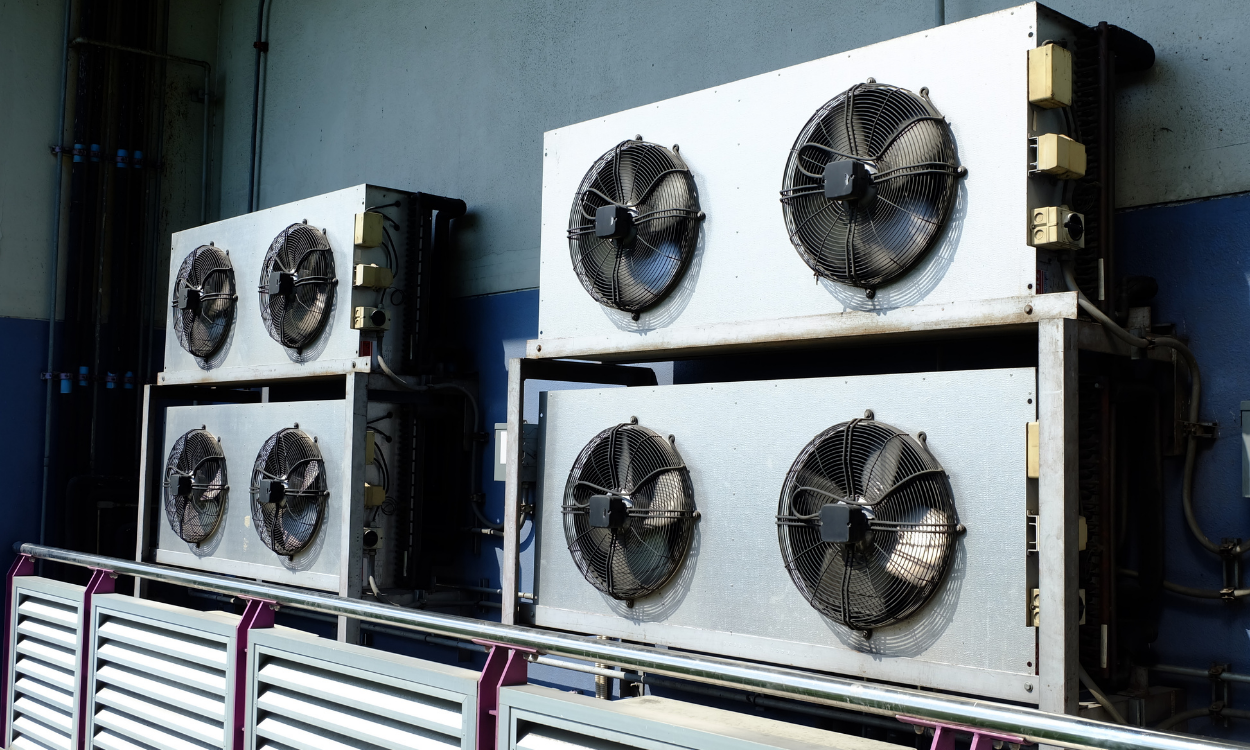

Warm Air Heating

Warm Air Heating

Warm air heating is one of the most widely used warehouse heating systems on the market today. The most effective warm air heaters draw the air in through a heat exchanger within the appliance and heats it up to the required temperature. The resulting warm air flow is then dispersed into the warehouse area using fans within the appliances, resulting in a comfortable working environment.

With a warm air heating system, it is critical that the heated air is uniformly dispersed throughout the entire facility, to maintain consistent temperatures. The addition of de-stratification fans may be required to ensure the air is distributed evenly around the warehouse to avoid any cold spots.

With energy prices increasing, Gas Warm air heating is more cost effective than electric equivalents.

You have a lot of alternatives when it comes to selecting a warm air heating system. These may be divided into three categories:

· Direct Fired

· Indirect Fired

· Electric Element

Let's look at each of these three choices separately so you can understand what they entail.

Even before recent increases in energy prices, electric unit heaters were 3 - 4 times as expensive to run as their gas equivalent.

Radiant Heating

Radiant Heating

This is a relatively recent heating technology utilised in specific facilities. It uses suspended infrared radiation-emitting tubes or plaque heaters to produce heat. While warm air heating systems merely warm the surfaces they touch, radiant heaters really warm the equipment and people who encounter them, so that the building warms up, heating the environment indirectly.

Asa result of the way radiant heating works, these heaters are frequently hung from the warehouse ceiling. This allows infrared radiation to spread out in a triangle pattern downward. Consider this a desk lamp. The more you raise the lamp up, the brighter the surface of your desk will be. By generating a large area of heat in a downwards and outward direction, radiant heating works similarly.

These systems are more tolerant of heat loss through high levels of air changes or heat loss, such as in older warehouses or where roller doors may be regularly opened for deliveries or shipments.

While Radiant Tube heaters provide many unique benefits on their own for warehouses, they can be combined to create the ultimate warehouse heating system. When you know which warehouse heaters will be the most efficient and cost-effective for your specific requirements, you can better determine which ones are going to work best for different zones of your warehouse. Don’t be afraid to combine both warm air heating commercial heaters for warehouse facilities with radiant heating, to achieve the heat you need for your facility at the most cost-effective price.

The capacity to put these installations in suitable spots, and the type of fuel used play a big role in which ones will be most beneficial for your specific storage space requirements

Which Heating System Will Be Best For My Warehouse?

As stated previously, there are many factors to consider when choosing the heating system for your warehouse, but the most important thing is to select a system that will work well in your specific climate. Heating systems that work well in cold climates may not be as effective in warm climates.

A Heating contractor, such as Winrow Building Services, can help you select the most efficient and cost-effective heating system for your requirements, and provide you with an estimate as to how much it will cost to heat your warehouse.

Installing Your Heating System

Once you have determined the size of the space and the type of heating system that is needed, you need to

install the heating system and set it up correctly. This includes installing ducts and vents in the right places and ensuring that they are properly insulated. You also need to make sure that your warehouse is properly insulated, so that heat does not escape through the walls and windows.

De-Stratification

Most warehouses have high roofs, which allows the structure to naturally provide more work and storage space for goods. It's only natural that heated air would be drawn to the top of a building with high roofs, and as your employees are unlikely to be working that high up, you'll be wasting energy heating the top of your warehouse, if you don't resolve this problem using the basic principle of destratification.

The last stage of de-humidification is known as stratification. Stratification simply refers to recirculating the warm air from the warehouse structure's roof to the occupied floor area. De-stratification fans may be easily installed on top of buildings to accomplish this. They can then use forced ventilation to send heated air back down towards the floor level where it will warm your employees and goods.

Heater Controls

To optimise the efficiency of your chosen heating system, it is also important to control it effectively, so that energy is not wasted unnecessarily. The controls utilised will be dependent on the layout of the warehouse and how individual areas are used. If an area is not in regular use, it may be appropriate to have separate controls in individual zones, so that areas used less are not heated to the same temperature as those areas in regular use throughout the day.

Setting controls will enable the heating to be automatically switched on so that the warehouse is a warm and welcoming environment for the arrival of your employees and visitors. Controls will also help reduce energy costs by automatically switching off at a pre-set time at the end of each working day.

What Have You Learnt?

- You have established what heating output will be required for your specific warehouse.

- You have assessed all the heating options available to you, including the three distinct types of warm air heating systems to select from - The direct-fired heater, indirect-fired heater, and electric element, as well as having the option of Radiant Tube heating.

- You will have taken advice from a heating contractor to help you decide which heating system will be the most efficient and cost-effective for your warehouse.

- You will have considered other implications of installing your heating system, such as ducting and the building insulation.

- You will also have assessed whether de-stratification fans should also be installed to optimise the heat generated and ensure it is not wasted in high areas of the warehouse.

- You will also have assessed the most appropriate controls for your heating system, to optimise the efficiency of your chosen heating system and ensure that energy is not wasted unnecessarily.

We hope our guide has given you some tips to help you choose the most efficient and cost-effective heating system for your warehouse, if you would like a consultation, contact us today.

Share This Post.

Need a Quote?

Is your business is looking for heating upgrade or an installation quote? Please call us on 08000 588 035 for a free quotation or fill out our contact form and we’ll get back to you as soon as we can.

If you could also attach some relevant images of the building and advise the building volumetric, it will help with our initial design assessment. Thank you.