Revolutionise Your Industrial Heating: Uncover the Power of Immersion Heaters with Winrow's Expertise

In the ever-evolving landscape of industrial and commercial heating solutions, immersion heaters stand out as a beacon of efficiency and sustainability. At Winrow Buildings, we understand the unique challenges faced by facility managers, business owners, and procurement specialists in selecting the right heating systems. This guide will delve into the intricacies of immersion heaters, offering insights into their working principles, types, benefits, and more.

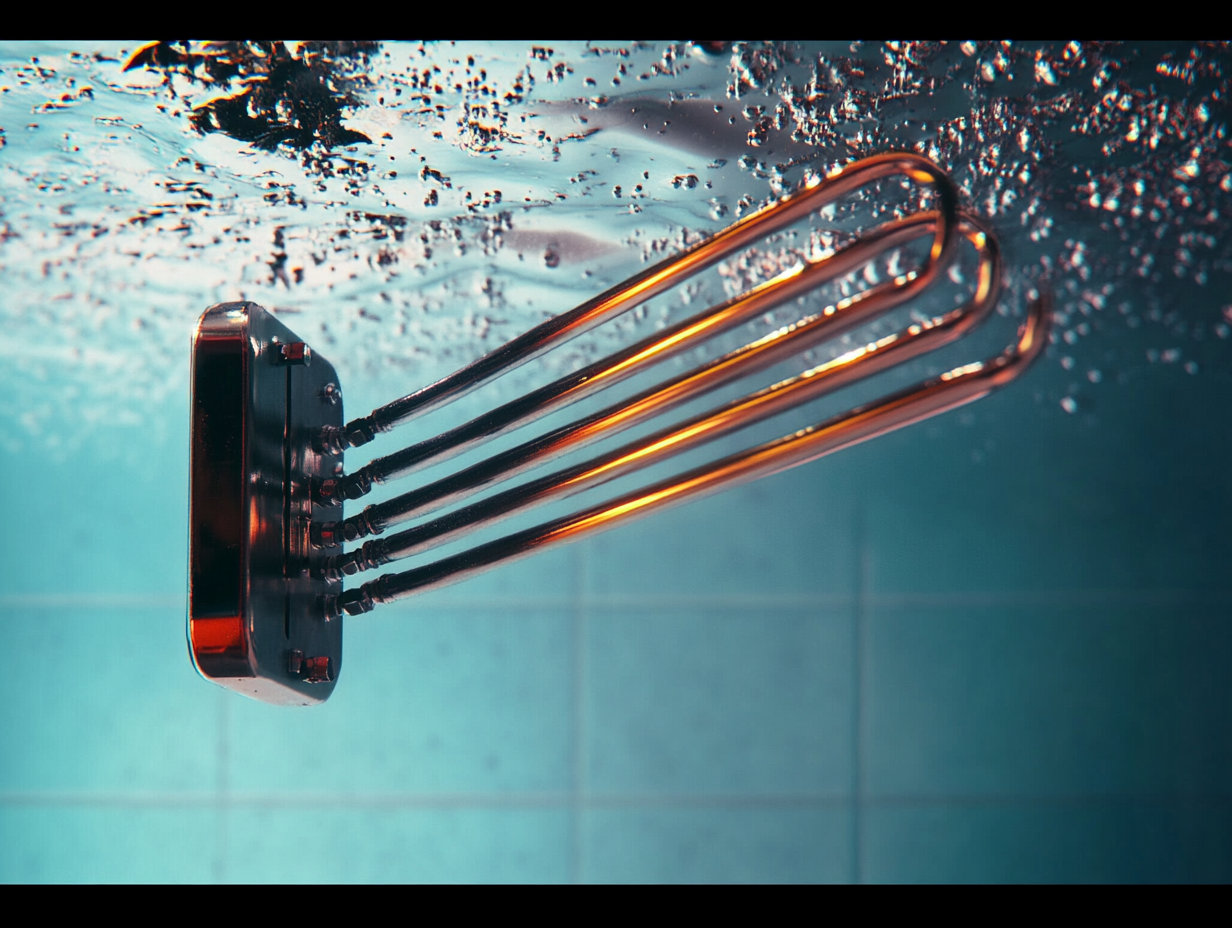

Introduction to Immersion Heaters

Imagine a world where your industrial heating needs are met with precision, efficiency, and sustainability. Immersion heaters are making this a reality for countless businesses across the globe. Whether you run a manufacturing plant or a commercial facility, understanding how immersion heaters work can provide significant advantages in terms of energy use and operational efficiency.

Immersion heaters are key components in many industrial and commercial settings, offering direct and effective heating solutions. They play a crucial role in applications ranging from chemical processing to food production, making them indispensable for energy-conscious business owners aiming to reduce costs and environmental impact.

This comprehensive guide explores the various facets of immersion heaters, their benefits, and how they can transform your business operations. Let's dive into the world of immersion heaters and discover how they can be a game-changer for your enterprise.

Understanding Immersion Heaters

Immersion heaters are electric heating elements that are directly immersed in the liquid to be heated, providing efficient and uniform heat distribution. This technology is particularly beneficial in industrial heating solutions, where precision and reliability are paramount.

Working Principles of Immersion Heaters

How Immersion Heaters Function

At their core, immersion heaters work by directly heating the liquid or substance they are immersed in. Unlike external heating systems, they transfer heat more efficiently because the heating element is in direct contact with the medium. This direct heating approach reduces energy loss and ensures faster heat-up times, making them highly efficient.

Key Components of Immersion Heaters

Immersion heaters generally consist of a heating element, a thermostat, and a control box. The heating element is usually made from materials like stainless steel or Incoloy, chosen for their durability and resistance to corrosion. The thermostat regulates the temperature, ensuring that it stays within the desired range, while the control box houses the necessary electrical connections and safety features.

Benefits of Direct Heating

The direct heating approach of immersion heaters offers several benefits. It provides uniform heating, which is crucial for processes requiring precise temperature control. Additionally, it minimizes energy wastage, making it a more sustainable option compared to other heating methods. This efficiency translates to cost savings for businesses, further enhancing their appeal in industrial and commercial applications.

Types of Immersion Heaters

Types of Immersion Heaters

There are several types of immersion heaters, each suited to different applications:

- Over-the-side immersion heaters: Ideal for containers where through-the-wall installation is not feasible.

- Flanged immersion heaters: Commonly used in tanks and pressure vessels, offering easy installation and maintenance.

- Screw plug immersion heaters: Perfect for small tanks and vessels, providing a compact and efficient solution.

Explore more about these options on our heating systems page.

Over-the-Side Immersion Heaters

Over-the-side immersion heaters are designed to be placed over the edge of a tank or container, with the heating element submerged in the liquid. They are ideal for applications where drilling holes in the tank is not feasible. These heaters are commonly used in processes involving viscous liquids or those requiring frequent maintenance.

Flanged Immersion Heaters

Flanged immersion heaters are mounted through a flange installed on the tank wall. This design allows for easy removal and replacement, making them suitable for applications requiring consistent and high-power heating. Industries such as oil and gas, petrochemicals, and water treatment frequently use flanged immersion heaters due to their robust construction and efficiency.

Screw Plug Immersion Heaters

Screw plug immersion heaters are screwed directly into the threaded opening of a tank or pipe. They are compact and perfect for smaller tanks or tight spaces. Their applications range from heating oils and solvents in small quantities to maintaining the temperature of hydraulic fluids.

Comparison of Materials and Design Features

Each type of immersion heater comes with its own set of materials and design features tailored to specific applications. For example, stainless steel is often used for its resistance to corrosion, while Incoloy is chosen for high-temperature applications. Understanding these differences can help you select the most suitable heater for your needs.

Benefits of Using Immersion Heaters

Benefits of Immersion Heaters

The advantages of using immersion heaters are manifold:

- Energy-efficient heaters: Direct heating minimises energy loss, translating to significant cost savings.

- Sustainable heating technologies: Align with eco-friendly practices, reducing your carbon footprint.

- Customisation: Tailored solutions to meet specific industrial needs, ensuring optimal performance.

Energy Efficiency and Cost Savings

One of the most significant advantages of immersion heaters is their energy efficiency. By directly transferring heat to the medium, they reduce energy loss and ensure quicker heat-up times. This efficiency translates to lower energy bills and reduced operational costs, making them a cost-effective solution for businesses.

Versatility Across Different Industries

Immersion heaters are incredibly versatile, with applications spanning various industries. From heating large volumes of water in commercial laundries to maintaining the temperature of chemicals in processing plants, their adaptability makes them a valuable asset. Their ability to provide precise temperature control also enhances product quality and process consistency.

Built-in Safety Features and Reliability

Modern immersion heaters come equipped with advanced safety features, such as thermal cut-off switches and overheat protection. These features ensure safe operation and prevent accidents, providing peace of mind to business owners. Additionally, their robust construction and durable materials contribute to their reliability and long service life.

Installation and Maintenance Considerations

Installation and Maintenance

Proper installation and maintenance are crucial for maximising the lifespan and efficiency of your immersion heaters. At Winrow, we offer comprehensive support and guidance, ensuring your systems are always running at peak performance. Visit our installation services page for more information.

Essential Tips for Proper Installation

Proper installation is crucial for the optimal performance of immersion heaters. Ensure that the heater is correctly positioned and securely mounted to avoid any operational issues. It's also essential to follow the manufacturer's guidelines for electrical connections and safety precautions. Consulting with a professional installer can help prevent common installation mistakes.

Guidelines for Regular Maintenance

Regular maintenance is key to extending the lifespan of your immersion heater. Periodically inspect the heating element for signs of wear or corrosion and clean it as needed. Check the thermostat and control box to ensure they are functioning correctly. Routine maintenance not only enhances performance but also helps identify potential issues before they escalate.

Safety Precautions and Troubleshooting Tips

Safety should always be a priority when working with immersion heaters. Ensure that the power supply is disconnected before performing any maintenance tasks. In case of any malfunction, consult the troubleshooting guide provided by the manufacturer or seek professional assistance. Keeping a record of maintenance activities can also help track the heater's condition over time.

Selection Criteria for Immersion Heaters

Selecting the Right Heater

Choosing the right immersion heater involves considering factors such as the type of liquid, required temperature, and installation environment. Our team at Winrow Buildings is here to assist you in making informed decisions. Learn more about our industrial heater selection process on our consultation page.

Factors to Consider

Selecting the right immersion heater involves considering several factors, such as material compatibility, wattage, and application needs. The material of the heating element should be compatible with the medium being heated to prevent corrosion and ensure longevity. The wattage should be sufficient to meet the heating requirements of the application.

Importance of Customisation

Customisation plays a vital role in selecting the ideal immersion heater. Tailoring the heater to meet specific industrial requirements ensures optimal performance and efficiency. Factors like the size and design of the heating element, the type of thermostat, and additional safety features can be customised to suit your needs.

How Winrow Buildings Can Assist

Winrow Buildings offers expert consultation to help you choose the right immersion heater for your application. Our team of specialists can guide you through the selection process, considering all relevant factors to ensure you get the best solution. We also provide customised heating solutions to meet unique industrial demands, ensuring maximum efficiency and reliability.

Innovations and Future Trends in Immersion Heater Technology

Innovations and Future Trends

The world of heating efficiency improvements is constantly evolving. Recent innovations in eco-friendly heating solutions are paving the way for more sustainable industrial practices. Stay ahead of the curve by exploring the latest trends with us.

Recent Technological Advancements

The field of immersion heater technology is continually evolving, with recent advancements enhancing their performance and efficiency. Innovations such as smart thermostats, advanced materials, and improved safety features are making immersion heaters more reliable and user-friendly. These developments are helping businesses achieve better energy management and operational efficiency.

Emerging Trends and Environmental Sustainability

Sustainability is becoming a crucial consideration in industrial operations, and immersion heaters are no exception. Emerging trends in the industry focus on developing eco-friendly heating solutions that reduce energy consumption and minimise environmental impact. For instance, the use of renewable energy sources to power immersion heaters is gaining traction, aligning with global sustainability goals.

Future of Heating Solutions in the Industry

The future of heating solutions lies in the integration of cutting-edge technologies such as IoT and AI. These technologies enable real-time monitoring and control of heating systems, optimising their performance and energy use. Additionally, advancements in material science are expected to yield more durable and efficient heating elements, further enhancing the capabilities of immersion heaters.

Conclusion

Immersion heaters play a critical role in industrial and commercial settings, offering efficient, reliable, and versatile heating solutions. Their ability to directly heat the medium, coupled with advanced safety features, makes them an invaluable asset for businesses aiming to enhance their operations.

Understanding the different types of immersion heaters and their specific applications can help you make informed decisions and select the most suitable solution for your needs. Regular maintenance and proper installation are essential to ensure their longevity and optimal performance.

At Winrow Buildings, we are committed to providing expert guidance and customised solutions to meet your unique heating requirements. Consult with our team today to explore how immersion heaters can transform your business operations and contribute to energy efficiency and sustainability goals.

By leveraging the benefits of immersion heaters, you can achieve significant cost savings, enhance productivity, and stay ahead in an increasingly competitive industry.

Immersion heaters offer a robust solution for industrial and commercial heating needs, combining efficiency, sustainability, and customisation. At Winrow Buildings, we pride ourselves on delivering expert guidance and tailored solutions to meet your unique requirements. Contact us today to revolutionise your heating systems and achieve unparalleled energy savings.

Share This Post.

Need a Quote?

Is your business is looking for heating upgrade or an installation quote? Please call us on 08000 588 035 for a free quotation or fill out our contact form and we’ll get back to you as soon as we can.

If you could also attach some relevant images of the building and advise the building volumetric, it will help with our initial design assessment. Thank you.