How to reduce heat loss in a warehouse

For a well-functioning, efficient warehouse, it is vital to keep it at a warm, comfortable temperature, especially in the winter months.

Not only do cold temperatures damage inventory that can lead to deterioration and the products being no longer suitable for use, but it also harms staff. A major component of a functioning warehouse is the employees who keep everything ticking over, and people are not able to work to the best of their ability in temperatures too hot or too cold. Everybody has a right to a comfortable working environment, and that is not the case if a warehouse is particularly cold.

Of course, you could keep the heating on but this is very costly and also has an environmental impact. A lot of companies are rightfully focused and conscious of their carbon footprint and being green, and leaving the heating on is not very environmentally friendly. If you are focused on lowering your carbon footprint, this will set you back.

So how can you keep your warehouse warm and reduce heat loss without resorting to leaving the heating on? Below you will find some cheaper alternatives for keeping your warehouse warm, even in the winter months.

Keep Your Heating System Efficient and Up-to-date:

While keeping your heating system on can be very expensive, it is still important to make sure you update your heating systems continually and make sure everything is in working order. A poorly maintained system can not only be inefficient and costly but also be a major safety risk, especially if your heating system is powered by gas.

Technology advances quickly and often, so it’s important to make sure your heating system is effective and efficient. If you have made any changes to your warehouse since your heating system was installed, it is advisable to check if your current heating system is still fit for purpose.

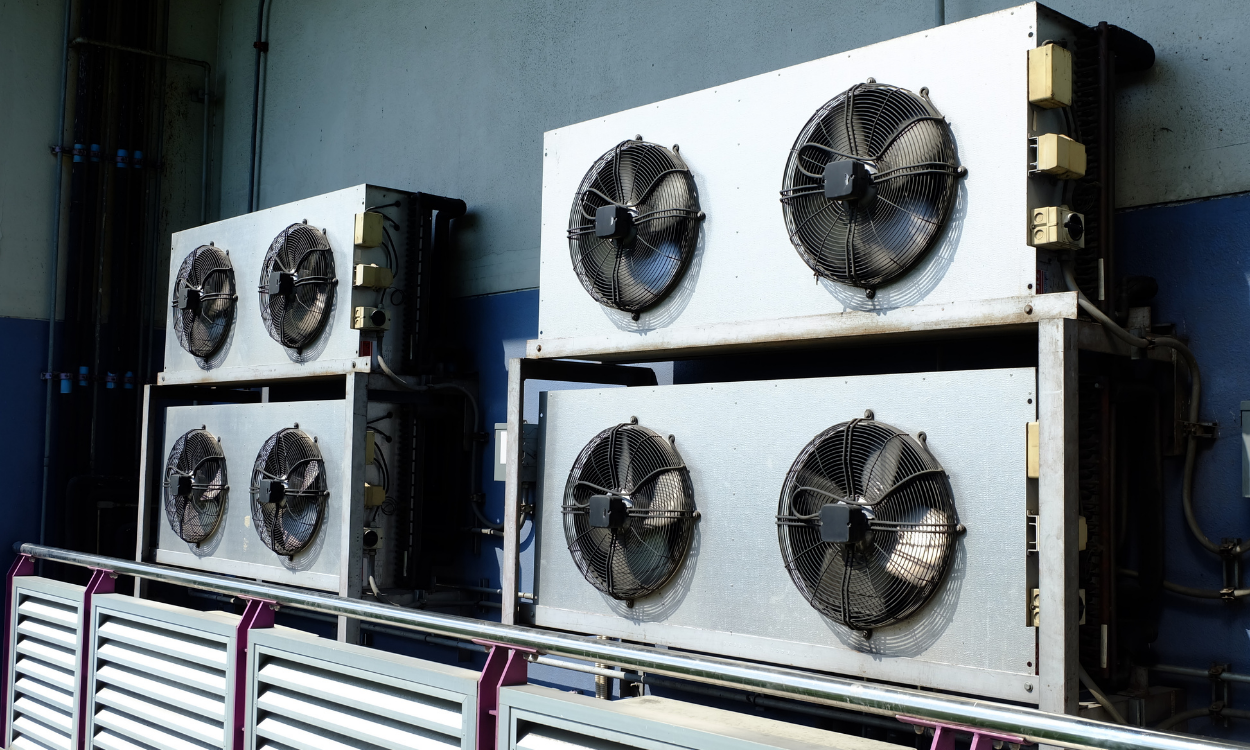

Utilise Fans For Proper Air Circulation:

Heat rises, often as drastically as 6 degrees celsius between the warehouse floor and the ceiling, so circulating air to make sure none of the heat goes away is very important.

The best and most cost-effective way to achieve this is by using a large, industrial-sized fan to circulate warm air around the warehouse. Utilising a fan can save up to 30 percent of your heating costs, and some companies who install these fans should be able to advise on optimal spaces to store the fan to get the best results.

Retain as Much Heat as Possible:

By design, warehouses have very large doors which make it impossible to completely eliminate heat escaping outside. However, there are cost-effective and effective ways to significantly reduce heat loss.

Insulated dock panel doors can help keep warm air in, but depending on how many dock positions need to be installed this can end up being quite costly. However, insulation kits tend to be less costly and are also easy to install.

Also, gaps around your dock doors can be a big cause of heat loss. If you are concerned this may be a problem for your warehouse, a good tip is to check the top, bottom, and sides of each door. If you can see daylight, you are most likely losing heat. You can fill these gaps with weather-stripping kits. These kits include stripping for the perimeter of the door, and a 5-inch double-loop bottom rubber astragal that makes sure the doors are shut tightly at the bottom. Not only do these kits reduce heat loss, but they also prevent bugs and debris from coming into the warehouse.

Dock seals or shelters are also crucial in reducing heat loss when trailers are loading and unloading. During the winter, high-traffic operations without seals lose a significant amount of heat every day and this is also the case with worn seals too. If your seals or shelters are in good condition, make sure each tractor-trailer is backed up tight against them before the dock doors open.

It is also a good idea to assess your dock leveller. If you use pit-mounted levellers, make sure the side and rear seals are in good, working order. If the seals on your dock leveller are worn this will let air in.

Install Windows and/or Skylights:

This may not be practical depending on how your warehouse is constructed, and if you rent or own it, but improving natural light and using heat generated by the sun is an effective and environmentally friendly way of reducing heat loss and keeping your warehouse warm.

Strategically placed windows or skylights can reduce energy costs during the winter and also improve the natural light in the warehouse. Less reliance on light fixtures can also significantly reduce your energy costs and is kinder to your electricity bill. Also, when you need to cool things down in the summer, just close the retractable blinds.

Use Air Curtains or High-Speed Doors:

Using air curtains or high-speed doors to partition some areas of your warehouse that are not used by employees often is an efficient, and cost-effective way to keep two separate areas temperature controlled. Air curtains and high-speed doors this can dramatically reduce your energy consumption.

FAQ

How do I keep my industrial unit warm?

Warehouses are usually heated using radiant heaters as opposed to warm-air heaters. Radiant heaters are energy-efficient warehouse heaters that keep the employees, floor, and sometimes the inventory warm. These heaters keep the warehouse warm even when the warehouse doors are open.

How do you stay cool working in a hot warehouse?

A hot warehouse can be just as detrimental to productivity, comfort, and safety as a cold warehouse.

Some tips for keeping cool in a hot warehouse include eating light meals such as salad with leafy greens, cucumbers, spinach, and tomatoes, or fresh fruit, or seafood like crab. Drinking coconut water is also a great way to stay cool and hydrated, and you should also try to avoid caffeine. Wearing thin, loose, and light-colored clothes is also advised, as darker colours absorb heat.

Winrow Industrial Services

If you have any queries about warehouse heating and or would like a quote on warehouse heating for your warehouse, Winrow are here to help. We are experts in installing, maintaining and repairing heating equipment for warehouses. Contact us today for a quote and more information about how we can help you.

Share This Post.

Need a Quote?

Is your business is looking for heating upgrade or an installation quote? Please call us on 08000 588 035 for a free quotation or fill out our contact form and we’ll get back to you as soon as we can.

If you could also attach some relevant images of the building and advise the building volumetric, it will help with our initial design assessment. Thank you.